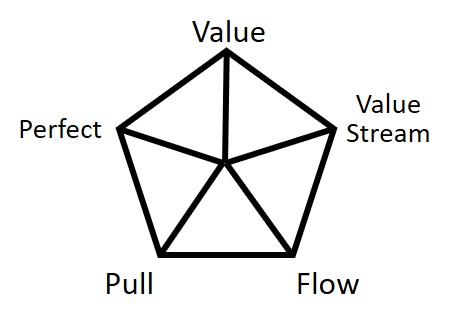

LEAN follows 5 principles: Value, Value Stream, Flow, Pull & Perfect(ion).

LEAN is often focussed on Efficiency - how much effort it takes to complete a task,

product, project etc.

And how much of that effort is useful (Value) versus how much is unnecessary (Waste).

And how much of that effort is useful (Value) versus how much is unnecessary (Waste).

Various tools, such as: Value Stream Mapping, The 8 Wastes, Visual Management etc.

help to identify and eliminate Waste.

6 SIGMA is a framework for reducing the amount of variation in a process.

6 SIGMA can be focussed on how Accurate and Predictable a task, product or process is,

and could be.

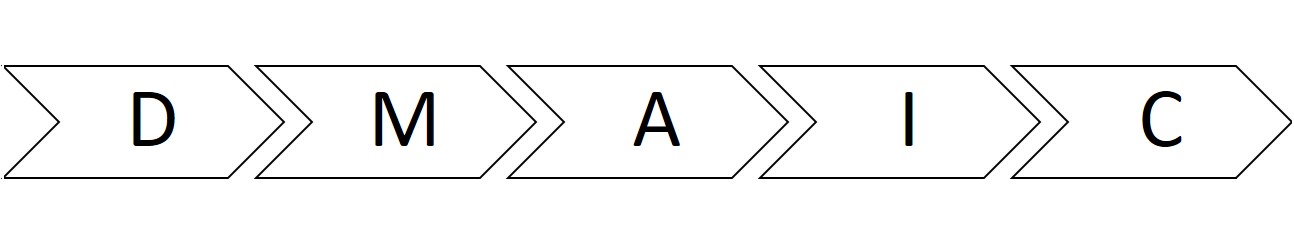

The framework DMAIC (Define, Measure, Analyse, Improve, Control) gives a structure to

understanding the causes of variation. Tools such as: Run Charts, Capability

Charts and Statistical Process Control are used.

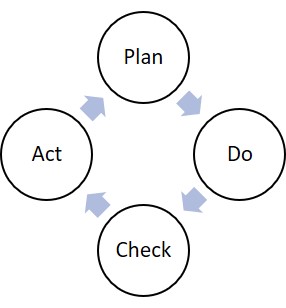

OPEX is a structured approach; working through: the Purpose, Measures

and Methods of an: Organisation, Function or Process.

OPEX takes a group of people though a layered set of tools that provide visibility and

capability across the 3 lenses of: Purpose, Measures & Methods. It is a 'hands-on'

approach that requires participation across all levels in the business.

You would expect to see: Team Huddles, Huddle-Boards, KPIs and A3 Problem-Solving templates.